Recycle Polyester HI-Vi Fabric

Detail Information

♻️ Recycled Polyester HI-Vis Fabric: Safety Meets Sustainability

The textile industry has increasingly turned its focus toward sustainable innovation, and Recycled Polyester High-Visibility (HI-Vis) Fabric stands as a key development in the protective workwear sector. This material successfully marries the non-negotiable safety requirements of industrial apparel with the growing global need for eco-conscious manufacturing.

What is Recycled Polyester HI-Vis Fabric?

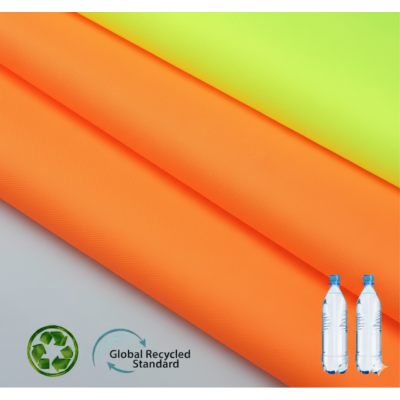

Recycled Polyester HI-Vis fabric, often referred to as rPET HI-Vis, is a synthetic material derived primarily from post-consumer plastic waste, such as used PET bottles. This waste material is given a "second life" by transforming it into the high-performance fibers necessary for safety garments.

The "HI-Vis" component means the fabric is engineered to meet strict international standards (like ANSI/ISEA 107 or EN ISO 20471) for conspicuity. This is achieved through:

Fluorescence: The fabric is brightly colored with fluorescent dyes (typically vivid yellow-lime or orange) to maximize visibility during daylight and twilight hours.

Retroreflection: It is combined with highly effective retroreflective material (tape or strips) that reflects light directly back to its source, ensuring the wearer is seen in low-light and nighttime conditions.The Manufacturing Process: From Bottle to FabricThe creation of rPET HI-Vis fabric follows a critical circular economy model:Collection and Sorting: Used PET plastics (mostly plastic bottles) are collected, sorted, and thoroughly cleaned to remove contaminants, labels, and caps.

Flaking and Melting: The clean plastic is shredded into small fragments called "flakes." These flakes are then melted down and often reformed into small, uniform chips or pellets.

Extrusion (Spinning): The molten plastic is extruded through tiny nozzles, known as a spinneret, to create continuous, long strands of recycled polyester fiber.

Weaving/Knitting and Dyeing: These rPET fibers are spun into yarn, then woven or knitted into the final fabric structure (often a durable weave or a breathable mesh/tricot). The material is then treated with fluorescent dyes and finished with reflective strips to achieve the required high-visibility rating.

Key Advantages and Environmental Impact

The adoption of rPET in high-visibility apparel offers compelling benefits over traditional, virgin polyester:

Waste Diversion: It directly repurposes non-biodegradable plastic waste that would otherwise end up in landfills, incinerators, or marine environments.Reduced Resource Consumption: The manufacturing process for rPET typically uses significantly less energy (up to 59% less) and less water compared to producing virgin polyester from petrochemicals.Lower Carbon Footprint: By reducing the reliance on crude oil as a raw material, rPET production results in lower CO2 emissions.

Performance and DurabilityCrucially for workwear, rPET fabric retains all the necessary performance characteristics of its virgin counterpart, ensuring worker safety and comfort are not compromised:High Durability: The fabric maintains excellent tensile strength and is highly resistant to abrasion, making it suitable for demanding work environments.

Functional Comfort: It is naturally wrinkle-resistant, quick-drying, and moisture-wicking, helping to draw sweat away from the body and keep the wearer comfortable during long shifts.

Colorfastness: The material holds fluorescent dyes extremely well, which is vital for retaining the required high-visibility color integrity even after repeated industrial washes.

In summary, Recycled Polyester HI-Vis Fabric provides a powerful solution that allows companies to align their safety protocols with their sustainability goals, effectively turning plastic pollution into reliable protective equipment.Polyester 85% cotton 15% Hi Vi yellow, Hi Vi orange: 270gsm

Cotton 50% recycle polyester 50% Hi Vi yellow, Hi Vi orange: 280gsm

Review

- Loading...

Related Products

Please send your message to us

- Name

- Mobile Phone

- *Title

- *Content

Keep in touch